Our business

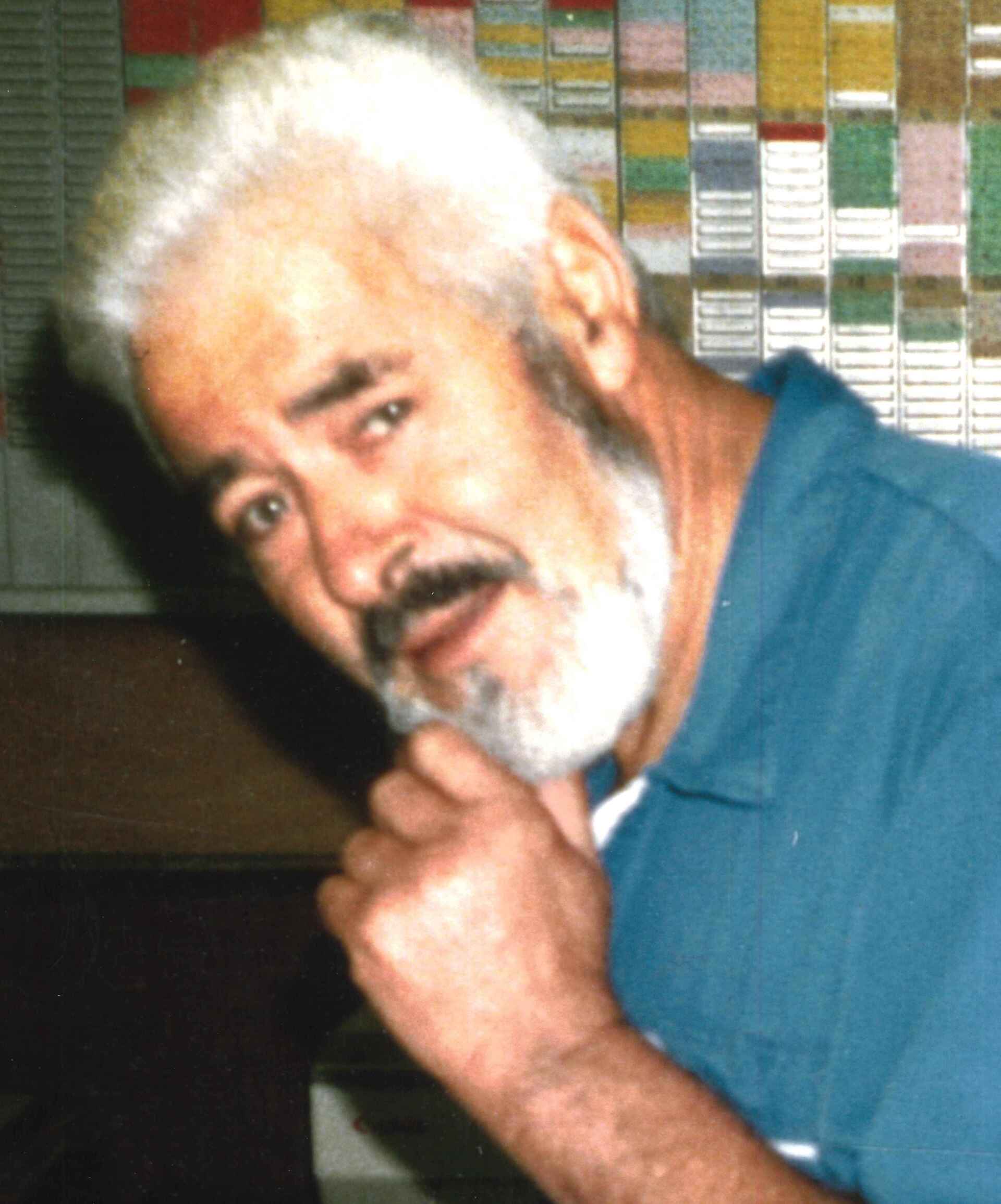

Albert

Perruchione,

the original production machinist at

Malouvis

The history of the PERRUCHIONE group began in 1974 on the initiative of Albert PERRUCHIONE who, while still employed in the bar turning industry, installed six machines in the garage of the family home.

In 1977, he founded his own business and moved into a 600 m² workshop.

The start-up grew rapidly as orders poured in. Very quickly, the workforce increased and Albert PERRUCHIONE's children started to join the company, too.

In 1980, he created the SARL Décolletage Malouvis. MALOU was chosen to pay homage to his wife, Malou, and in relation to the company's main production component, screws.

Today, among the eight children Albert and Marylou PERRUCHIONE raised, two are at the head of the company, Évelyne and Rodolphe. The company's continuity is assured, and the Sallancharde company is now one of the jewels in the crown of the

French precision parts manufacturing industry serving the aeronautical, railway and industrial sectors.

"With a goal of family independence, our service offers sustainable and rational performance"

Being a family business allows for unparalleled responsiveness.

Malouvis operates in the spirit of an industrial 4.0 system.

As performance is at the heart of our company, it is only natural that we invest every year in new, numerically controlled precision production equipment to meet the requirements of all the sectors we operate in.

Which materials for the machining of parts?

Malouvis offers a wide range of materials for the machining of parts. To help with this, Malouvis uses an internal coding system inspired by the Ministry of Defence's guide to writing standard references (Guide 14G1). Furthermore, Malouvis is referenced under the NATO number FAT06, and we use a normative language that allows us to meet all specifications for machining standard parts or parts to drawings. As professionals in the field of bar turning and component production, Malouvis utilises normative references in conjunction with AFNOR for raw materials. Consequently, whatever the request, we have the appropriate materials for the production of the parts concerned. Some examples:

Blank die material according to AIR9160 material code: BC-CC-CM-CF-BE

Stainless steel material, Z2CN18-10, Z10CNT18-10, Z30C13…

Special materials: Inconel, Monel, Aluminum series 2000 to 6000, Cupro beryllium, titanium TA6V

Our machine workshop is at the service of quality

When you turn to Malouvis, you can be sure to expect respect, quality, requirements and thorough controls throughout the manufacturing process, as well as in post-manufacturing, as well. Asa bar turning firm, Malouvis is certified to ISO 9001, EN 9100 and AQAP 2110, which confirms the company's competence in the manufacture and marketing of high-quality fasteners in both standardised and customised versions.